Not only providing guidance, guide rollers also offer additional support. One common application of guide rolls is for use in conveyor systems, which are most often utilized in the industrial manufacturing industry for materials and parts handling. Read More…

Harwood Rubber Products provides top quality rubber rollers and a variety of custom products. We are capable of producing a great diversity of rolls and coverings for a broad customer base.

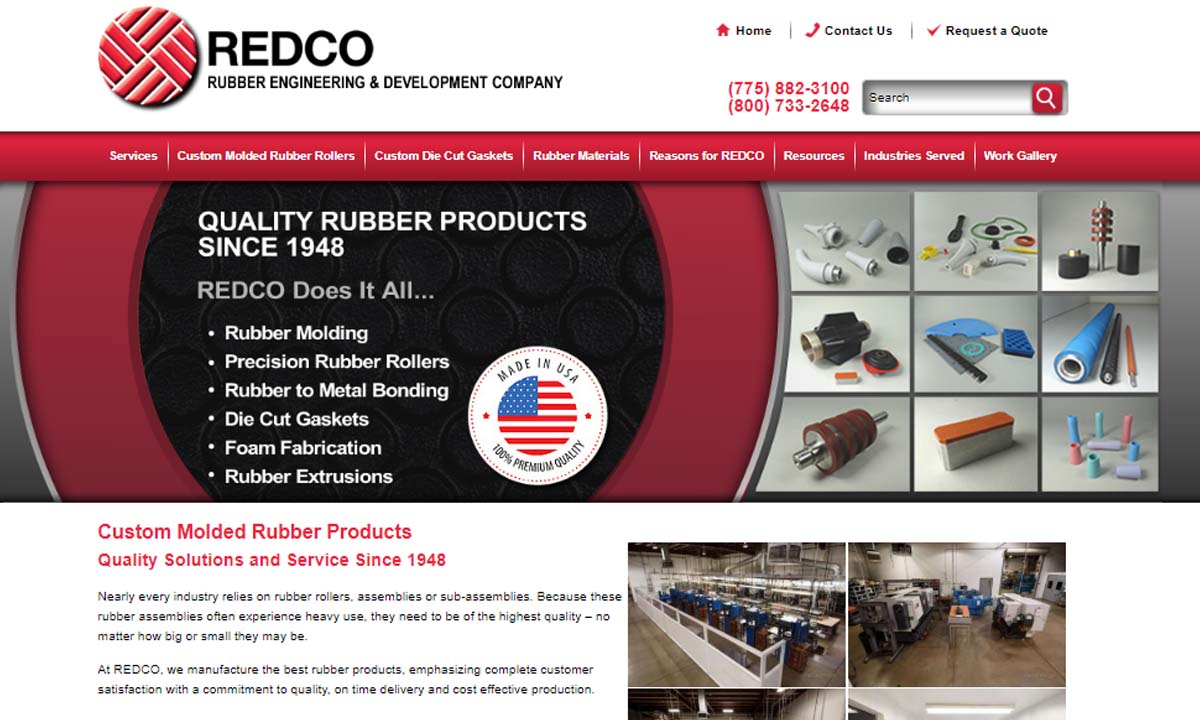

Since 1948, REDCO Rubber Engineering & Development has been manufacturing rubber rollers, idler rolls and conveyor rollers. We serve industries such as computers, printers and paper handling.

Our guide rollers are made from the highest quality materials in the industry. We take pride in adhering to our company values, like integrity and honesty. As a family owned and operated company, we like to treat customers like our own family. We will always look for the best prices and the prefect solution. Give us a call today to see how we can help you meet your goals!

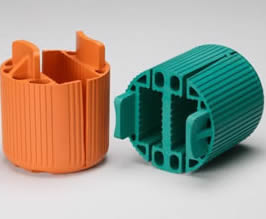

TPC, Inc. is a dedicated and trusted manufacturer of rollers. We manufacture rollers in all shapes, sizes, designs, and colors to meet the needs of our customers and keep their process moving. Our team of experts is dedicated to the production and innovation of our products. As a result, TPC, Inc.’s custom-fit solutions are perfected for customers of all industries.

More Guide Roller Manufacturers

Industries that benefit from the use of guide rollers include automotive manufacturing, for use in car lifts, tensioners and other power transmission applications; construction, in off-road equipment such as lift trucks and traveling cranes for material handling applications; mining, for underwater and underground applications; healthcare, for health imaging equipment such as magnetic resonance imaging (MRI) scans; and various processing industries, such as metalworking, textile production, paper milling, foil production, film manufacturing and more.

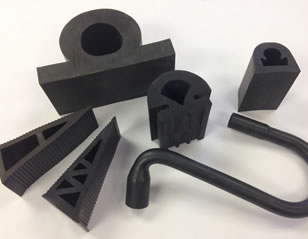

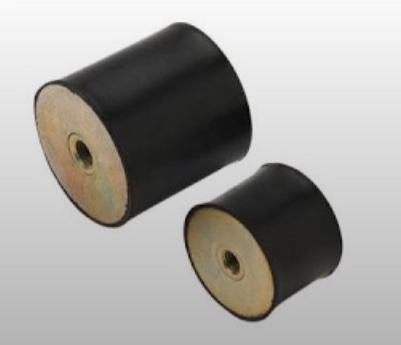

Typical materials used to manufacture guide rollers include silicone, polyurethane, nylon and vulcanized rubber. These materials are used because they provide adequate hardness, since guide rolls must be able to provide uniform surface tension in applications such as conveyor belts and web converting in order for the processes to run smoothly. Although they can also be formed from plastic or metal, when they are formed as rubber rolls, the two main processes used to fabricate guide rollers are compression molding and injection molding.

In injection molding, the rubber material is heated to a molten state and then injected into a split die chamber or mold cavity, which is clamped shut. Next, the mold is cooled by running water over it, and the cooling allows the roller to form. In compression molding, the rubber material is also heated to a molten state. However, instead of being injected into the mold, the molten rubber is placed in an open mold. The mold is closed by top force known as a plug member and pressure is applied in order to achieve the desired shape. Since guide rolls must be manufactured from hard materials, they are often encased in jackets to ensure additional tensile strength.

For jacketed guide rollers, a rubber to metal bonding process is used. In rubber to metal bonding, rubber is adhered to a metal substrate, such as steel or aluminum, through the use of a bonding agent. The bonding agent generally consists of polymer-solvent solutions, a primer coat based on phenolic-style resins and a top layer consisting of a mix of polymers and other materials. Constructed with or without a shaft, guide rollers offer easy installation and maintenance, a low rotating mass, easy maintenance and reduced friction.

Rubber Extrusions

Rubber Extrusions Rubber Molding

Rubber Molding Rubber to Metal Bonding

Rubber to Metal Bonding Rubber Tubing

Rubber Tubing Vibration Absorbers

Vibration Absorbers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services