Industries that require the use of drive rolls include automotive manufacturing, for use in timing belts and other power transmission applications; healthcare, for imaging equipment such as magnetic resonance imaging (MRI) and computerized axial tomography (CAT) scans; mining, for bulk material handling applications; office equipment design, for machinery such as printers and scanners; and lumber, in equipment such as plywood machinery, which is used to turn logs and peel the wood. Read More…

Harwood Rubber Products provides top quality rubber rollers and a variety of custom products. We are capable of producing a great diversity of rolls and coverings for a broad customer base.

Since 1948, REDCO Rubber Engineering & Development has been manufacturing rubber rollers, idler rolls and conveyor rollers. We serve industries such as computers, printers and paper handling.

Our guide rollers are made from the highest quality materials in the industry. We take pride in adhering to our company values, like integrity and honesty. As a family owned and operated company, we like to treat customers like our own family. We will always look for the best prices and the prefect solution. Give us a call today to see how we can help you meet your goals!

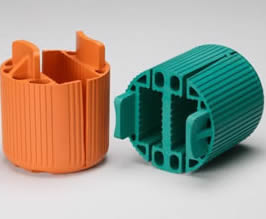

TPC, Inc. is a dedicated and trusted manufacturer of rollers. We manufacture rollers in all shapes, sizes, designs, and colors to meet the needs of our customers and keep their process moving. Our team of experts is dedicated to the production and innovation of our products. As a result, TPC, Inc.’s custom-fit solutions are perfected for customers of all industries.

More Drive Roller Manufacturers

Additional industries that benefit from drive rollers include construction, food and beverage, packaging, chemical processing and more. Able to be motorized or manual, drive rollers are often manufactured from materials such as polyurethane (PU), vulcanized rubber and silicone rubber. Different styles of drive rollers are manufactured for varying applications, and differences include varying load carrying capabilities, surface area design and material strength.

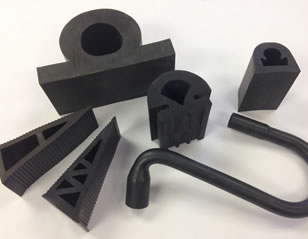

Drive rollers are typically manufactured through molding processes - either injection or compression. When formed using the injection molding process, small pieces of rubber are heated to a molten state and then injected into the mold cavity. Water is run over the mold in order to cool it and form the roller. When formed during compression molding, the rubber is again heated to a molten state, but instead of being injected into the mold, the material is placed into an open, heated mold.

Next, extreme pressure is applied by closing the mold by means of a top force or a plug member. The resulting pressure pushes the molten rubber against the walls of the mold, and both heat and pressure are maintained until the roller is cured and fully formed.

Drive rollers may have a grooved or altered surface area in order to better fit certain applications. In some instances, this surface area design is achieved by knurling. Knurling is a forming process, typically done on a lathe, which is used to create a rough patterned texture on the surface of a metal or rubber in order to provide grip or enhanced aesthetics. In addition to altered surface areas, drive rolls differ from other types of rubber rolls in that they have integral shafts with a keyway that allows sprockets or gears to run the roller.

Rubber Extrusions

Rubber Extrusions Rubber Molding

Rubber Molding Rubber to Metal Bonding

Rubber to Metal Bonding Rubber Tubing

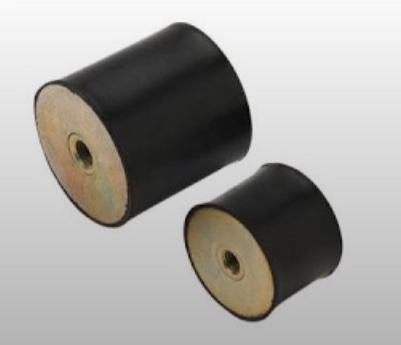

Rubber Tubing Vibration Absorbers

Vibration Absorbers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services