Industrial rollers are rubber rolls that are used in manufacturing equipment, particularly in stamping presses, conveyor systems, bending machines, printing presses, and similar devices. As long as they serve industrial purposes, a variety of roller types can be designated as industrial rollers. Read More…

Harwood Rubber Products provides top quality rubber rollers and a variety of custom products. We are capable of producing a great diversity of rolls and coverings for a broad customer base.

Since 1948, REDCO Rubber Engineering & Development has been manufacturing rubber rollers, idler rolls and conveyor rollers. We serve industries such as computers, printers and paper handling.

Our guide rollers are made from the highest quality materials in the industry. We take pride in adhering to our company values, like integrity and honesty. As a family owned and operated company, we like to treat customers like our own family. We will always look for the best prices and the prefect solution. Give us a call today to see how we can help you meet your goals!

TPC, Inc. is a dedicated and trusted manufacturer of rollers. We manufacture rollers in all shapes, sizes, designs, and colors to meet the needs of our customers and keep their process moving. Our team of experts is dedicated to the production and innovation of our products. As a result, TPC, Inc.’s custom-fit solutions are perfected for customers of all industries.

More Industrial Roller Manufacturers

They are helpful conveyors when paired with high-speed sorting equipment because these rollers can reduce product impact from higher speeds, making them excellent for situations where materials and products accumulate during the manufacturing process. Although they appear to be just a simple product, industrial rollers have undertaken numerous innovations in order to remain relevant as manufacturers continue to modernize their processes.

How Industrial Rollers are Made

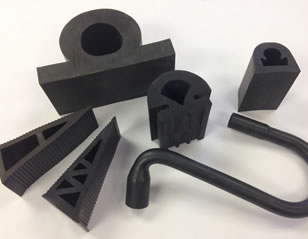

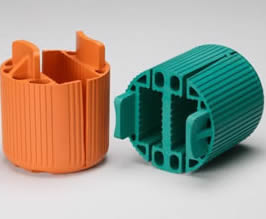

Industrial rollers are manufactured through a variety of techniques including molding, casting, and, in some circumstances, extrusion. However, injection molding and compression molding are the most common techniques for producing industrial rollers. In injection molding, rubber is heated, injected, and cooled to create the roller in the cavity of a closed split die chamber or mold. In compression molding, the roller shape is created by heating the rubber before pressing it firmly into a heated mold.

Industrial rollers may also be made using the extrusion technique, which involves heating rubber, forcing the molten rubber through a die with a pin in the middle, and forming the roller's hollow interior. Although some rollers are made solely from rubber (or plastic), metal machining techniques like metal stamping are typically used to create the metal core found in most industrial rollers.

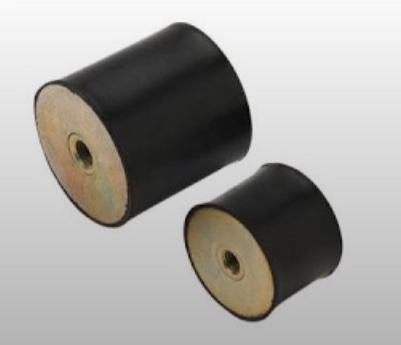

With the same kind of pin-equipped die used in extrusion, metal stamping creates metal cores from metal material that is later inserted. The bottom of the die is attached to the press bed, while the top is attached to the press slide. The metal is subsequently forced through the die as a result of pressure from a punch (often referred to as a ram) and forms the roller core. A rubber jacket is then created over the metal core using a metal-to-rubber bonding method. During this procedure, a bonding chemical is used to adhere rubber to a metal substrate.

Types of Industrial Rollers

Drive Rollers

Drive rollers are material-handling devices with a cylinder shape that move objects through a machine, procedure, or environment. When used in resource-handling applications, they provide time, space, and energy efficiencies. Motorized driving rollers are powered by internal electric motors and revolve in response to a motor's direct action. Linking motors provide rotational energy to belt-driven drive rollers. Idler rollers, the rollers found within the metal bars running alongside the conveyor belt, may be added in connection with the belts, or in specific areas coming into contact with other moving elements. They are useful for sustaining conveyed materials in between drive rollers but do not get direct mechanical input from a power source. They are the only type of roller mechanism used in gravity conveyors.

Roller Conveyors

A roller conveyor is a frame supported by a number of rollers on which items can be conveyed manually, automatically, or by gravity. Roller conveyors can be adapted in a variety of ways for a variety of functions. These devices are utilized in warehouses or industrial plants. Roller conveyors can make conveyor systems or automated systems more versatile, serving as transfer, diverter, and stopping mechanisms. Roller conveyors are available in mild steel, galvanized steel, plastic, and stainless steel.

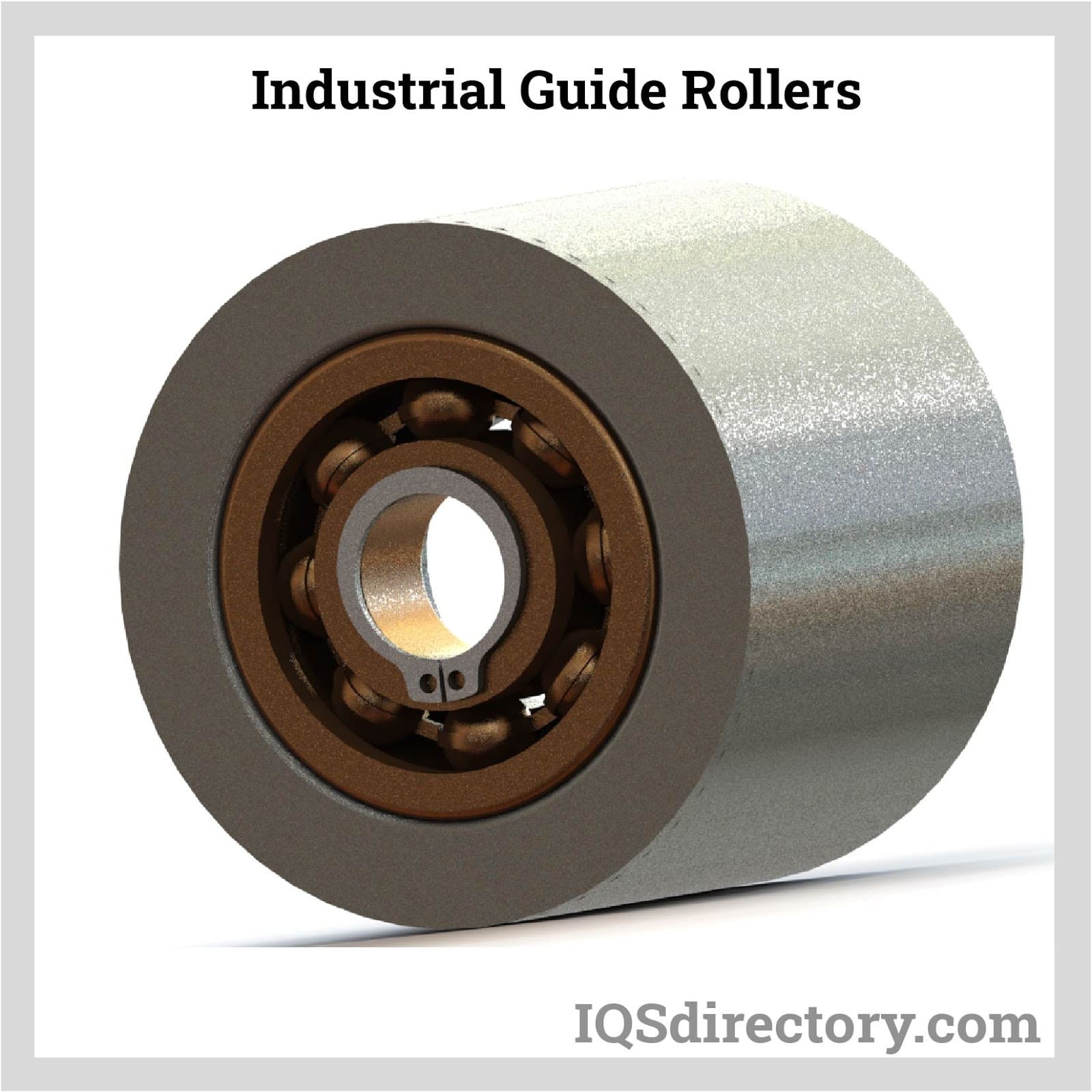

Guide Rollers

Guide rollers help keep items in line while moving through machinery. In specialized conveyor systems, these rollers can be mounted horizontally as cantilevers, as belt guides, or vertically for directional control. The guide roller's function is to keep an object's integrity and alignment intact while it is moving through the manufacturing process. This might be a door, a fence, or even a drawer. Any moving object can be directed by a guide roller into following the path created by the roller and track in a straight and systematic fashion.

Rolling enables effortless movement with the least amount of resistance; it allows workers to quickly and easily move heavy objects across various stages of production. Additionally, this avoids needless harm to the goods being placed into position along these same production phases. The installation of guide rollers as conveying mechanisms, and as a means for keeping items aligned through manufacturing processes, has numerous benefits. Their use enables the conveyor system to operate more effectively, durably, and safely.

Advantages of Industrial Rollers

- Industrial rollers are a necessary component of any factory or warehouse. They improve the manufacturing process by efficiently directing items through machinery and the various stages of production. They also improve worker safety, reducing or eliminating the need to lift heavy items and preventing items from falling onto workers.

- Depending on the kind of items they handle, factories, warehouses, and other industrial organizations encounter a variety of challenges. Since no two facilities operate in exactly the same manner, some of their logistical issues can only be resolved with the dependability of an industrial roller. For instance, industrial rollers can help industries that handle poisonous or chemically reactive materials convey their compounds with little, to no, human interaction.

Choosing the Right Industrial Roller Supplier

To make sure you have the most positive outcome when purchasing industrial rollers from an industrial roller supplier, it is important to compare at least 5 companies using our list of industrial roller suppliers. Each industrial roller supplier has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the supplier for more information or request a quote. Review each industrial roller company website using our proprietary website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple industrial roller companies with the same message.

Rubber Extrusions

Rubber Extrusions Rubber Molding

Rubber Molding Rubber to Metal Bonding

Rubber to Metal Bonding Rubber Tubing

Rubber Tubing Vibration Absorbers

Vibration Absorbers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services