Lamination can be explained as the process of bonding two or more sheets or layers of material, typically plastic, in order to create a laminate, which is a thin sheet of non-fabric protective material. Read More…

Harwood Rubber Products provides top quality rubber rollers and a variety of custom products. We are capable of producing a great diversity of rolls and coverings for a broad customer base.

Since 1948, REDCO Rubber Engineering & Development has been manufacturing rubber rollers, idler rolls and conveyor rollers. We serve industries such as computers, printers and paper handling.

Our guide rollers are made from the highest quality materials in the industry. We take pride in adhering to our company values, like integrity and honesty. As a family owned and operated company, we like to treat customers like our own family. We will always look for the best prices and the prefect solution. Give us a call today to see how we can help you meet your goals!

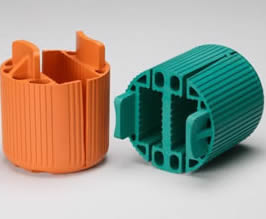

TPC, Inc. is a dedicated and trusted manufacturer of rollers. We manufacture rollers in all shapes, sizes, designs, and colors to meet the needs of our customers and keep their process moving. Our team of experts is dedicated to the production and innovation of our products. As a result, TPC, Inc.’s custom-fit solutions are perfected for customers of all industries.

More Laminating Roller Manufacturers

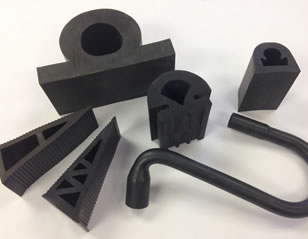

Since lamination requires heat in order to properly bond the two materials, laminating rolls must be fabricated from materials that are capable of high heat-resistance such as silicone, which is capable of withstanding temperatures of up to 500º F (260° C). Additional elastomeric materials capable of withstanding high temperatures include fluorocarbons, EPDM, neoprene, butyl rubber, nitrile butadiene (NBR) and chlorinated polyethylene.

Laminating rollers are essential in a broad spectrum of industries, including marine products manufacturing, for lamination of the underside of offshore vessels; woodworking, for the lamination of table tops, chairs and other pieces of furniture; industrial manufacturing, for processing and assembly equipment such as web converting machinery; and printing, for the lamination of important documents, identification cards and other types of paper requiring a protective outer coating. Often, laminating rolls are constructed with a metallic core, such as aluminum, steel or stainless steel, with the elastomeric material bonded onto the core through a rubber-to-metal bonding process.The rubber-to-metal bonding process involves the rubber, the bonding agents and the substrate. Once the rubber is determined, the bonding agent can be determined, and they generally consist of a polymer-solvent solution, a primer coat based on phenolic-style resins and a top layer of polymers and other materials. To apply the bonding agent, a primer coat must be sprayed over a slightly wider area than the topcoat through the use of a barrel spraying machine. The substrate and the rubber must then be pressed together to enable the bonding to occur.

Once manufactured, for lamination there must typically be three sets of rollers: a drive roller, a guide roller and a laminating roller. There must be a 1:1:1 ratio of these three roller types. The guide roller and the laminating roller rotate in direct correlation to the rotation of the drive roller.

While the drive roller moves the material, the guide roller stretches the material and the laminating roller laminates the material as it is stretched and extruded between the rollers. Lamination offers several benefits, including enhanced color and contrast of materials, protection from abrasion and increased material strength.

Rubber Extrusions

Rubber Extrusions Rubber Molding

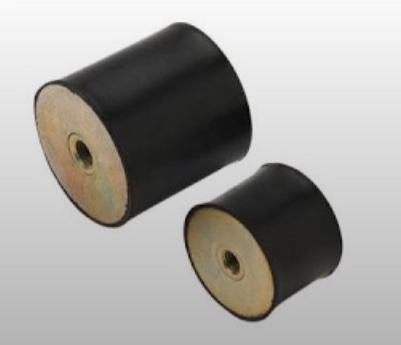

Rubber Molding Rubber to Metal Bonding

Rubber to Metal Bonding Rubber Tubing

Rubber Tubing Vibration Absorbers

Vibration Absorbers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services