Rollers, in general, are cylindrical devices that can rotate around an axis. They are used in various industries for applications such as conveying, printing, laminating, and more. Rubber rollers, specifically, are rollers that have a rubber covering or coating on their surface, which provides desirable properties like traction, elasticity, and resistance to wear and tear, making them suitable for tasks such as material handling, printing presses, and other specialized applications. Read More…

Harwood Rubber Products provides top quality rubber rollers and a variety of custom products. We are capable of producing a great diversity of rolls and coverings for a broad customer base.

Since 1948, REDCO Rubber Engineering & Development has been manufacturing rubber rollers, idler rolls and conveyor rollers. We serve industries such as computers, printers and paper handling.

Our guide rollers are made from the highest quality materials in the industry. We take pride in adhering to our company values, like integrity and honesty. As a family owned and operated company, we like to treat customers like our own family. We will always look for the best prices and the prefect solution. Give us a call today to see how we can help you meet your goals!

TPC, Inc. is a dedicated and trusted manufacturer of rollers. We manufacture rollers in all shapes, sizes, designs, and colors to meet the needs of our customers and keep their process moving. Our team of experts is dedicated to the production and innovation of our products. As a result, TPC, Inc.’s custom-fit solutions are perfected for customers of all industries.

More Roller Manufacturers

Applications

Rubber rollers are widely used in various industries due to their versatile properties, finding applications in tasks ranging from material handling to printing and packaging. In the printing industry, rubber rollers play a vital role in transferring ink from the plate to the substrate, ensuring consistent print quality and paper feed. They are also commonly employed in conveyor systems to facilitate the smooth movement of materials in manufacturing, packaging, and logistics. In laminating and coating machines, rubber rollers provide pressure for bonding layers together and ensuring even coverage of coatings on materials like paper, plastic films, textiles, and metal sheets. Additionally, they are utilized in the textile industry for dyeing, printing, and finishing operations, safeguarding delicate fabrics during processing.

Rubber rollers are essential components in various printing and packaging machinery, such as flexographic and gravure printers, where they transfer ink or coatings onto packaging materials like labels, corrugated cardboard, and flexible films. In the paper industry, rubber rollers aid in calendering processes, which smooth out and improve the paper’s surface for enhanced printability and quality. Moreover, as industrial rollers, they provide traction, shock absorption, and vibration dampening in heavy machinery and equipment used in printing and metalworking. Print finishing equipment, such as laminators, varnishing machines, and foiling presses, incorporate rubber rollers to add protective layers and a final touch to printed materials.

Rubber rollers are also used in embossing and engraving machines, allowing the creation of intricate patterns and designs on materials like paper, leather, and metals. Their versatility, durability, and traction properties make them indispensable in these and many other industrial applications, significantly contributing to improved efficiency and enhanced quality across various manufacturing processes.

The History of Rubber Rollers

Before rubber, people used rollers made from materials like wood and metal. Rubber rollers would not exist if not for the discovery of vulcanization, developed by Charles Goodyear in 1840. Goodyear found that by adding a sulfur and lead and dropping the rubber mixture into a stove, it would become weather resistant, chemical resistant, water resistant and elastic.

Shortly after, as engineers experimented with the process, manufacturers of the Industrial Revolution discovered that they could add soft or hard rubber to a hard steel shaft to perform material nipping (pinching or squeezing) applications that the steel alone could not. Thus, the rubber roller was born.

After the rubber roller was invented, manufacturers in a wide variety of industries began using it for their purposes. For example, starting in the 1920s, publishers began relying on rubber rollers to spread thin glue layers and apply ink to their printing plates.

In the years ensuing, little has changed about the rubber roller, except the rubber materials with which it is made and the applications for which it used. Now, both the material possibilities and the application possibilities for rubber rolls have grown exponentially.

Design

Production Process

Rubber Fabrication

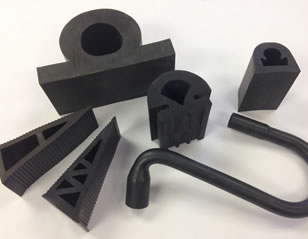

Standard rubber roller manufacturing involves a rubber fabrication step, which can be achieved either by plying method, extrusion, casting, or die press.

Plying involves the calendering process, during which, to make calendered rubber sheeting, rubber is passed through a combination of rollers. As the rubber sheet moves through the rollers, it is smoothed and flattened. Using this process, two types of polymer can be sandwiched together, if an application demands. Once the calendered sheet is ready, the sheet becomes a rubber cover of an iron core or another metal core. With that, it is a rubber roller. Based on client requirements, sheets can be polished, glazed or embossed.

Extrusion is the most common manufacturing method that involves an extruder. With this method, a rubber profile of fixed cross-sectional can be made continuously by-passing rubber through a die. In this process, raw material is heated by passing it through a screw mechanism, which heats material by a combined action of pressure and temperature, and then the material is pushed through the die. The critical step in this fabricating technique is curing, which involves conditioning the rubber product in a controlled environment where it is exposed predetermined temperature and pressure. The curing process gives the structural strength to a rubber product by removing porosity.

Casting, inarguably, is the oldest way of giving shape to a range of materials. From automobile engines to high-end sculptures, have been crafted by this method. Whatever the material is, all is molded by the same principle, which involves pouring of raw material in a mold and then exposing it to an oven for a period of time that cures it and sets it in a predefined shape.

Die press rubber fabrication commonly involves a hydraulic press and a die. The die gives the shape to the raw rubber, whereas press provides pressure and heat to cure the rubber product. The process begins by filling raw rubber into a metal mold, and then a hydraulic arm fitted with a die presses the mold and provides heat and pressure. Unlike extrusion, the press method is not continuous, thus is not as efficient as extrusion.

Roller Manufacturing

Rubber rollers are usually manufactured via casting or molding, but they may also be made through extrusion.

Casting processes are utilized only with rubber rollers that have metallic cores. In this case, cores are formed through a metal casting process like stamping, after which they are bound to a rubber coating. Binding is carried out using a bonding agent that is usually made of polymer-solvent solutions, a primer coat based on phenolic-style resins and a top layer of mixed polymers and other various materials.

Rubber roller molding processes include compression molding and injection molding; these are used for solid rollers.

Extrusion of rubber rollers takes place when manufacturers heat chosen elastomeric material(s) and squeeze the molten material through a die that has a pin in the center to fabricate the hollow tube.

Grooving

The next step involves surface grooving. There are a number of grooves that can be created on a surface of rubber, including square, trapezoidal, “V”, double edge saw, half circle, and round. Moreover, on a rubber roll, these grooves can be made vertically, horizontally, helically, worm, diamond cut groove and screw threaded.

Inspection

At the end of this step, the products are inspected for aberration.

Materials

The elastomeric materials from which manufacturers can choose from are fairly varied. Each material has its own strengths and weaknesses, but all of them have some level of resistance to water, wear, certain chemicals and heat extremes.

Among the many, a few materials that are frequently used to fabricate rubber rollers include: EPDM, silicone, nitrile, neoprene, polyurethane and natural rubber. Metal core rollers are usually made with steel, stainless steel, aluminum or another metal that fits application requirements.

Considerations and Customization

When designing a rubber roll for a specific application, manufacturers consider a number of factors, such as: chemical contact (required chemical resistance/inertness), standard requirements, required length, load capacity, thickness, shape and tapering, etc. They also consider roller speed. If a roller is exposed to high speeds with large loads, manufacturers generally recommend you buy rubber rolls with a core that can be water cooled. When rubber is nipped, it releases heat—called hysteresis heat—and water cooling is an effective way to contain that heat.

Manufacturers can easily customize rubber rolls per your specifications. For example, you may order rubber rolls to meet unique diameter and length specifications, and you may order them in a variety of thicknesses and colors. In addition, manufacturers can use different types of rubber to make rollers inert against chemicals based on an application. They can also put on specialty finishes or coatings and specialty shaping. Find out more by discussing customization with your prospective supplier.

A Note on Load Capacity

A typical rubber roller has the maximum load capacity of 100 kilogram-force centimeter (kgf/cm) when force is exerted linearly. However, the load capacity of a roll varies with the rubber hardness, materials, and the rotation speed, as well as thickness of rubber, the temperature range, type of the core, and construction. Therefore, we recommend you check the rubber roller load capacity while installing them. If needed, your manufacturer can design a roller with greater load capacity of 100 kgf/cm. Ask your manufacturer if your requirement falls in this range.

Features

Rubber rolls share several common features that contribute to their effectiveness in various applications. One of the primary features is the rubber outer covering, which comes into direct contact with the material being processed or conveyed. This outer covering is typically made from high-quality rubber compounds, chosen based on the specific requirements of the application. The rubber’s properties can vary, including hardness, elasticity, chemical resistance, and temperature resistance, depending on the intended use. The rubber outer covering plays a vital role in providing traction and grip on the material, preventing slippage and ensuring a smooth transfer process.

Another essential feature is the metal core, which provides structural support and stability to the rubber roll. The metal core is usually made from materials like steel or aluminum, offering strength and durability to withstand the stresses of operation. The core’s design may vary depending on the application, with variations in diameter, thickness, and internal structure.

Additionally, there are several variations and customizations of these features to suit specific needs. Different industries and applications may require specialized rubber compounds for the outer covering, tailored to handle unique materials or environments. For instance, in the printing industry, the rubber outer covering of rollers may be formulated to provide exceptional ink transfer and resist chemical degradation from printing inks. In the paper industry, the rubber rolls may have a softer outer layer to avoid damaging the delicate paper during processing.

Similarly, the metal core can be modified to meet specific requirements. For heavy-duty applications, a reinforced metal core may be used to handle higher loads and resist deformation. In certain cases, the metal core might incorporate specialized coatings to enhance corrosion resistance or reduce friction between the core and the rubber outer covering.

Overall, the combination of the rubber outer covering and the metal core enables rubber rolls to perform efficiently in diverse industrial settings, contributing to improved traction, durability, and reliability across various applications. The ability to tailor these features to suit specific needs further enhances the versatility of rubber rolls in meeting the demands of different industries.

Types

Ink rollers, also called printing rollers, apply ink to paper and other materials; rollers may contain ink within themselves or they may be engraved with a pattern.

Laminating rollers, made of heat resistant materials like silicone rubber, are heated up to 500°F to laminate materials on both a small and large scale.

Drive rollers are movement focused rubber rollers. Often used for converters and web machines, they operate using integral shafts equipped with keyway that acts as a gear.

Guide rollers, or idler rollers, provide support to other roller systems like conveyors, but they do not actually move anything.

Grooved rollers are called so because they have a grooved pattern, usually a spiral, U or V; grooved rollers are usually part of moving systems like belt driven conveyor systems.

Conveyor rolls, or conveyor rollers, simply move, or convey, materials.

Live shaft rollers are designed to withstand difficult environments and high load quantities; they have external bearings in which both the roller shaft and the roller rotate.

Dead shaft rollers have internal bearings located at the same place as a spinning roller that spins around a stationary shaft.

Cleaning rollers are used to remove dirt, dust and other contaminants from different surfaces. They are highly specialized to each surface they clean.

Spreader rollers, frequently machined with specialized groove designs, like herringbone, spiral, circumferential and lateral-fluted, are commonly used for webs spreading machinery and other spreading applications. In the case of web spreading machinery, spreader rollers stretch and spread the web to prevent and fix wrinkles.

Stinger rollers, finally, are configured very much like dead shaft rollers, but they are designed specifically for marine applications.

Urethane rollers, also known as polyurethane rollers, are made from a synthetic roller from polyurethane. They are inexpensive to produce, they have many great qualities, including: shock resistance, formability, durability, elasticity and strength. Urethane rollers are best for use in: data storage, packaging and assembling, printing, material handling, measurement systems and office equipment.

EPDM rollers are heat resistant, corrosion and oxidation resistant and weather resistant, and are thus quite versatile. However, they do not hold up well against petroleum products.

Industrial rubber rollers are rubber rolls used in industrial applications, primarily manufacturing machines like: stamping presses, conveyor systems, bending machines, printing presses, and the like. Many types of rollers can be categorized as industrial rollers, as long as they perform industrial applications.

Advantages of Rubber Rolls

Rubber rollers offer numerous benefits that make them highly preferred over other materials, including metal, for various roller applications. One significant advantage is their excellent traction and grip on the materials being processed or conveyed. This is particularly crucial in industries like material handling and printing, where a secure grip on substrates or conveyed materials ensures smooth and efficient operations. In contrast, metal rollers may not provide the same level of traction and are more prone to slippage issues.

Rubber’s inherent elasticity allows these rollers to absorb impact and vibrations, making them ideal for applications requiring precision and material integrity. In printing presses or machinery handling delicate materials, rubber rollers minimize the risk of damage caused by excessive impact or vibration. Additionally, rubber rollers generate less noise during operation, offering a quieter work environment compared to metal rollers, which is especially beneficial in industries where noise reduction is essential.

Another advantage of rubber rollers is their non-marring property, as they are less likely to leave marks or scratches on delicate materials. This feature makes them suitable for applications involving sensitive surfaces like paper, textiles, and certain films. Furthermore, rubber rollers can be manufactured with specific rubber compounds that exhibit excellent chemical resistance, making them suitable for applications involving exposure to chemicals, oils, and solvents that might corrode or degrade metal rollers.

The customizability of rubber rollers is another notable advantage. The properties of the rubber outer covering, such as hardness, elasticity, and surface finish, can be tailored to suit different materials and processing conditions. This flexibility allows rubber rollers to be used across a wide range of industries and applications, accommodating diverse requirements.

While metal rollers have their advantages, such as higher load-bearing capacities and durability under extreme conditions, the unique characteristics of rubber rollers make them a preferred choice for applications where their specific properties can enhance performance, minimize damage, and improve overall operational efficiency. As a result, rubber rollers find extensive use in industries like printing, packaging, material handling, textiles, and many others.

Proper Care for Rubber Rolls

Rubber rolls, just like every other component, have their limits and should be used as per the instructions. To learn how to extend the working life of your rubber rolls, read the advice below.

Temperature Regulation

High temperature is an enemy of rubber, regardless of the rubber type used for making rolls. Therefore, it is best to avoid rapid heating while using rubber rolls. You should also avoid rapid heating because the bonding adhesive usually has low heat resistance even lower than the rubber. If your application demands work under high temperature, we recommend you keep your roller temperatures under operating range by water cooling them.

Storage

To avoid damage, you also need to store them properly. While storing a rubber roll, you must hold the shafts and stand them upright, so the rubber part does get exposed to other materials. Moreover, since rubber can be damaged by UV light, we recommend that you store your roller in a cool and dark place.

Maintenance Checks

During regular maintenance checks, you need to pay special attention to a number of roller parts. These include: ball bearings, axes and gears. Watch out for: worn-out ball bearings, bearings misaligned along their axes, overloaded gears, faulty gears, unbalanced rollers and deflected rollers.

Standards

Rubber rolls are subject to a number of different standard requirements, depending on their application. For example, rubber machinery like extruders, generally speaking, any rubber roll you purchase should meet ISO standards for rubber products. In addition, most rubber rolls are rated according to ASTM International’s rubber hardness scale. This is helpful for determining if the roll meets your requirements.

Things to Consider

If you’re looking for a set of precision rubber rolls that will serve you well, you need to work with the right manufacturer. While there is an abundance of companies out there ready to take your business, there are only some that have proven their worth in the field. On this page, we’ve listed some of those proven rubber roll manufacturers. Before looking them over, we recommend you take time to make a list of specifications that you can reference as you browse. Remember to include details like your budget, your deadline, your delivery preferences and your customer support preferences. Once you’ve done that, you can get to browsing.

As you browse the companies we’ve listed, whose profiles are sandwiched in between these informational paragraphs, frequently cross-reference your specifications list for compatibility. Pick out three or four suppliers to whom you’d like to speak directly, then reach out to each of them for a quote. After you’ve had your conversations, you can compare and contrast the suppliers. Choose the company you believe will serve you with the most integrity and deliver the best products. Good luck!

Rubber Extrusions

Rubber Extrusions Rubber Molding

Rubber Molding Rubber to Metal Bonding

Rubber to Metal Bonding Rubber Tubing

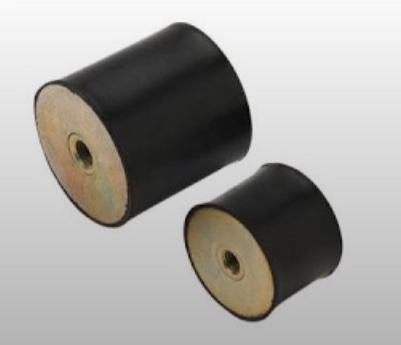

Rubber Tubing Vibration Absorbers

Vibration Absorbers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

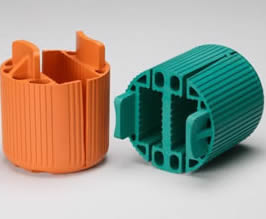

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services